UHT solutions: Boosting competitiveness in the food industry

28/08/2024

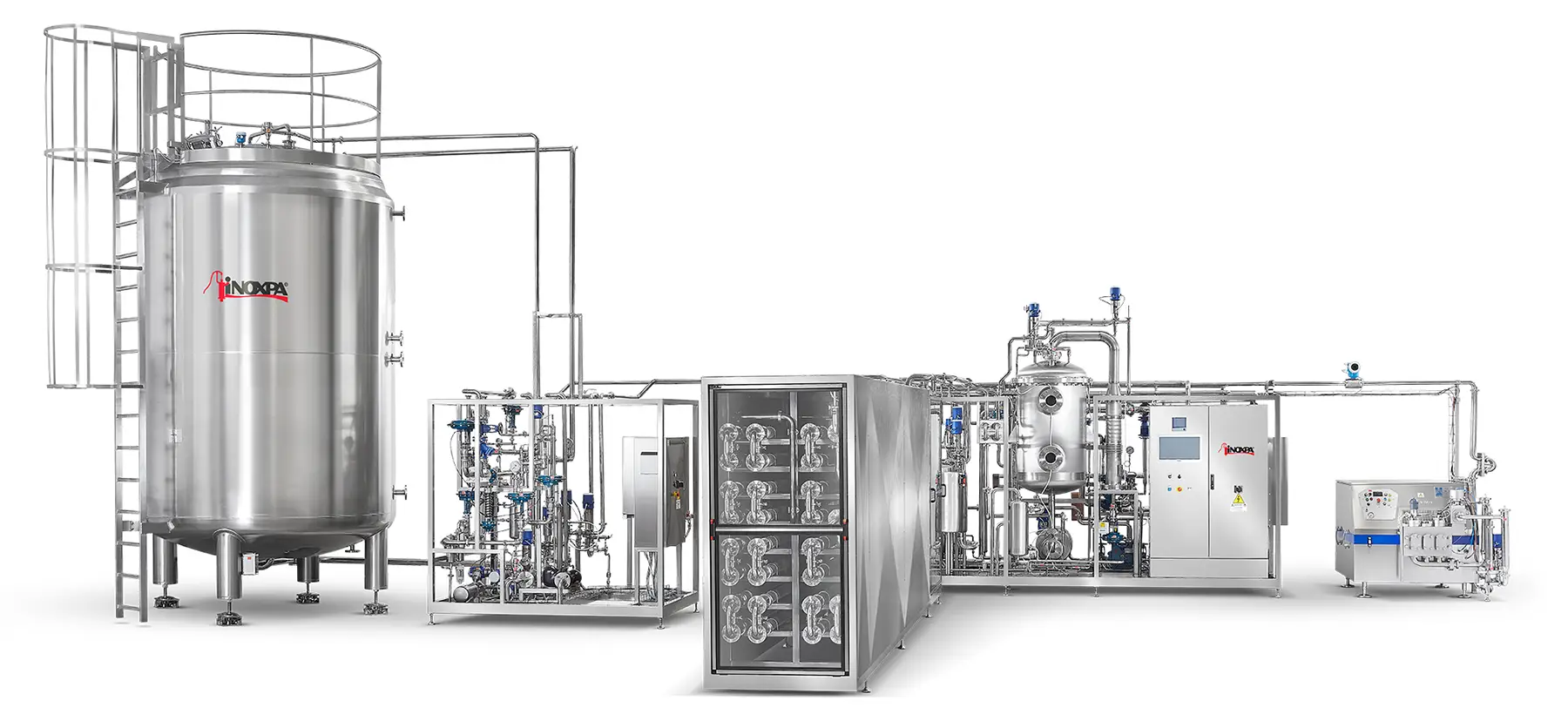

SystemsINOXPA’s UHT solutions help food companies to grow their competitiveness.

Our UHT systems for the Ultra High Temperature treatment (sterilisation) of dairy and plant-based products, fruit juices, beverages, soups and, in general, any liquid and low-viscosity food, represent the core of the process plant of many companies in the food industry.

UHT treatment is a processing technology employed to kill microorganisms and microbial spores in order to guarantee safe and stable shelf life to food products by exposing them to ultra-high temperature over a short time. The products treated in such a way can be maintained under unrefrigerated conditions for months.

Different chemical, physical and organoleptic properties of food products make the careful selection of the most appropriate UHT treatment crucial.

Heating mode, heat exchanger design as well as temperature program are key aspects to be considered in order to guarantee the highest possible efficiency and a gentle treatment of the product; the latter being essential to retain as much as possible the nutritional and organoleptic characteristics.

The nature of the product determines the most appropriate heating mode to be selected from indirect type, through tubular heat exchanger, or direct type, a combination of tubular heat exchanger for heat regeneration and steam injection for product sterilisation.

The heating of the product occurs in tubular heat exchangers designed to offer high thermal efficiency and optimum cleanability to ensure long operation and reduce production downtime.

In indirect heating systems, the sterilisation takes place by heating the product to the required temperature in the tubular heat exchanger, without it coming into contact with the heating media (steam).

In direct heating plants, the product is first heated by heat recovery in the tubular heat exchanger, while the sterilisation temperature is achieved by steam injection followed by flash cooling to remove the excess water originated by steam condensation.

Efficient thermal exchange and very accurate control of the injected steam are to guarantee thermal-stress free process to preserve the characteristics of the fresh product.

INOXPA systems can be completed with either aseptic or non-aseptic homogenisers and aseptic tanks to offer our customers complete and tailor-made solutions for their UHT treatment needs.

Advanced and user-friendly control systems, make the operation of the INOXPA UHT plants efficient and reliable allowing their full integration into any existing SCADA system.

Contact

Other news

-

23/01/2025

23/01/2025Industrial sourdough plants

INOXPA industrial sourdough plants are a comprehensive solution for producing craft bread on a large scale.

Systems -

20/11/2024

20/11/2024ME-6100 RE: new recirculation tank bottom mixer

This new family of mixers further expands such an important range for our sector as we cover the mixing needs for a wide range of applications.

Mixing -

30/09/2024

30/09/2024Bioreactors: maximum precision and efficiency in every process

INOXPA bioreactors are the definitive solution for more precise, efficient and sustainable biotechnological production.

Systems