New MCR counter-rotating agitator

30/06/2022

MixingINOXPA presents the new MCR counter-rotating agitator.

This new agitator adds to our product portfolio in the agitator range and is a very important project for our business. It represents progress in terms of consolidating the agitator range for use across all industries.

We have started a new stage, we adapt our agitators to customer requirements and needs, using standardised components in a quicker and more efficient manner. The mixing elements adapt to the geometrical requirements of the equipment and the process parameters.

This new agitator configuration is our solution for mixing and homogenisation of medium and high viscosity products for a wide range of very common applications that are often requested in our sector for pharmaceutical, cosmetic and food products.

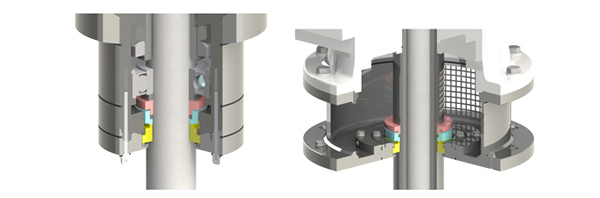

The MCR agitator has two coaxial shafts connected to two geared motors that rotate in opposite directions. The central shaft has propellers optimized for mixing in low-viscosity phases and the outer shaft is connected to an anchor with scrapers ensuring a faster and more homogeneous heat transfer.

The MCR agitator range comprises 8 models with capacities ranging from 30 to 10,000 litres.

Main features:

- Modular and fully configurable design. The modular approach offers benefits such as lower prices, shorter delivery times and better adaptability.

- Hygienic design. Every internal component is optimised to enable CIP system cleaning, SIP sterilisation and complete drainage.

- Easy maintenance and disassembly. The anchor propeller can be removed completely. It can be disassembled for the installation of the agitator and for maintenance. The agitator can be inserted through the flange without the anchor or propellers. The anchor’s arms and the propellers can be inserted via the manhole and fitted onto the agitator inside the tank.

- Independent geared motors, with H1 food oil. RAL9016 white colour. Geared motors with high efficiency coaxial gears as standard. Option to fit a range of drive types with ATEX certification.

The new design with hygienic scrapers prevents the product from stagnating. Every internal area is sealed to prevent product entry.

Stainless steel lantern, designed for fitting different sealing systems. Sealing system with interchangeable support. Single mechanical seal as standard.

Should you have any queries or need more information, our technical department can provide advice and help you choose the most suitable model based on your needs and requirements https://www.inoxpa.com/company/contact