New INNOVA single seat valves

22/03/2024

Valves and fittings

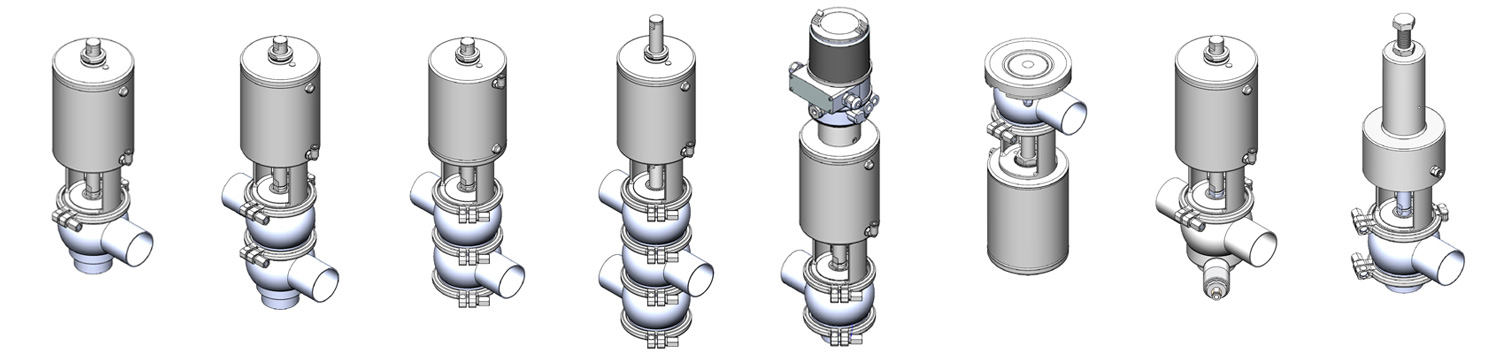

INOXPA is launching a new range of single seat valves with significant design and feature innovations and improvements.

The main objectives when designing the new range of INNOVA single seat valves were standardising the actuators’ scale and force, optimising and simplifying the design, as well as interchangeability of different sizes of actuators and valves.

The new actuators derived from a revision of how the forces are scaled, resulting in more standardised increments.

This new scaling has also resulted in a reduction of actuator dimensions, deriving in a significant air consumption saving.

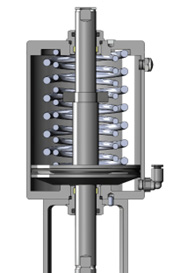

This was achieved by fitting a second concentric spring, which makes the actuator more reliable, resistant and durable. By way of example, the new double-acting actuator consumes half the amount of air.

This was achieved by fitting a second concentric spring, which makes the actuator more reliable, resistant and durable. By way of example, the new double-acting actuator consumes half the amount of air.

Achieving a cleaner design with no seals, holes or screws was another objective, making a more hygienic actuator in line with sanitary certifications. This involved welding the actuator, meaning a lot less parts are used, plus costs are reduced and no maintenance is required.

The shaft and the piston are a single piece, making the assembly simpler, and the internal dynamic seals have been improved and they are “X-Ring” type, extending the actuator’s useful life.

A new lantern system has been developed, whereby all different sizes, whether DIN or OD, are marked with their size and have the same type of connection with the actuator, using a nut, this fulfils another of this new programme objectives - interchanging different actuator sizes with different valve sizes.

This system means a larger or smaller actuator can be fitted based on an installation’s specific operating pressure, with the maximum operating pressure of 10 bars achievable with all valve sizes.

This system means a larger or smaller actuator can be fitted based on an installation’s specific operating pressure, with the maximum operating pressure of 10 bars achievable with all valve sizes.

For example, 4 different actuators can be installed with a DN 65 valve, from T2 to T5, and operating at pressures ranging from 4.7 to 10 bar.

To sum up, the actuators have been reduced in size and consume less air, the external design is cleaner and more hygienic with no seals, screws or holes, the scaling of forces is more standardised and efficient, the components (seals and springs) have been significantly improved, and the lantern-actuator connection system enables interchanging different actuator sizes with different valve sizes.

Contact

Other news

-

23/01/2025

23/01/2025Industrial sourdough plants

INOXPA industrial sourdough plants are a comprehensive solution for producing craft bread on a large scale.

Systems -

20/11/2024

20/11/2024ME-6100 RE: new recirculation tank bottom mixer

This new family of mixers further expands such an important range for our sector as we cover the mixing needs for a wide range of applications.

Mixing -

30/09/2024

30/09/2024Bioreactors: maximum precision and efficiency in every process

INOXPA bioreactors are the definitive solution for more precise, efficient and sustainable biotechnological production.

Systems