New INNOVA Mixproof double seat valves

12/01/2024

Valves and fittings INOXPA is launching new INNOVA Mixproof double seat valves for their P, S and T models.

INOXPA is launching new INNOVA Mixproof double seat valves for their P, S and T models.

This new programme involves a series of physical and functional improvements that aim to enhance performance, extend durability and reduce the environmental impact.

Some internal and external aspects of the actuators have been redesigned to achieve that objective. Externally, the manufacturing has been streamlined with the aim of simplifying both assembly and maintenance.

The number of actuator variants has been reduced from 10 to 3 due to a new system of lanterns, which now have a measurement for each valve size and specific measurements for DIN and OD.

These lanterns have been redesigned by both reducing the number of screws required to assemble them and and also their size.

Internally, one of the piston’s runs has been significantly shortened, with the aim of reducing air consumption and shortening the lower seat’s opening and closing response time.

The springs have also been improved, extending their durability, and all dynamic seals are now of the “quad-ring” type.

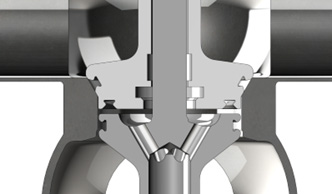

The housings are made of one machined piece, with the aim of improving the structure and maintenance of valves in the manifolds.

The housings are made of one machined piece, with the aim of improving the structure and maintenance of valves in the manifolds.

The geometry of the seats and shafts has been redesigned to reduce the discharge of the cleaning product.

The upper and lower shafts open during CIP processes to clean the seals and internal part of the shaft, leading to a small amount of cleaning product flowing out, which is normally collected in the manifold tray. There are two reasons for reducing this amount of product to a minimum: product savings and pollution reduction.

To sum up, the new mixproof valves are more effective, their efficiency is improved due to lower air and cleaning product consumption, which also helps reduce the environmental impact.

Contact

Other news

-

23/01/2025

23/01/2025Industrial sourdough plants

INOXPA industrial sourdough plants are a comprehensive solution for producing craft bread on a large scale.

Systems -

20/11/2024

20/11/2024ME-6100 RE: new recirculation tank bottom mixer

This new family of mixers further expands such an important range for our sector as we cover the mixing needs for a wide range of applications.

Mixing -

30/09/2024

30/09/2024Bioreactors: maximum precision and efficiency in every process

INOXPA bioreactors are the definitive solution for more precise, efficient and sustainable biotechnological production.

Systems