Innovation and commitment in pump manufacturing

13/12/2023

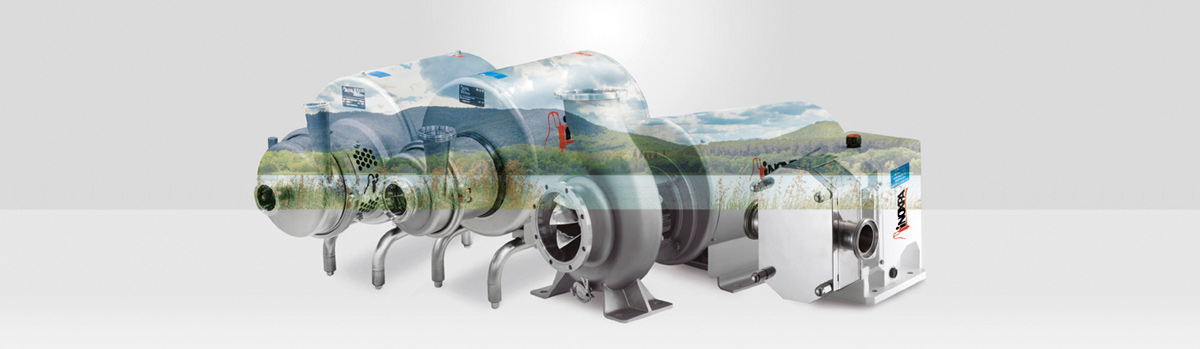

Pumps INOXPA constantly aims to set the standard for stainless steel pump manufacturing, ensuring they can meet food and pharmaceutical industry customer demands. The commitment is to a hygienic design, compliance with international certification and directives, like FDA, Regulation (EC) No 1935/2004 and USP Class VI, while also ensuring high performance.

INOXPA constantly aims to set the standard for stainless steel pump manufacturing, ensuring they can meet food and pharmaceutical industry customer demands. The commitment is to a hygienic design, compliance with international certification and directives, like FDA, Regulation (EC) No 1935/2004 and USP Class VI, while also ensuring high performance.

Innovation

We will soon launch a new premium hygienic lobe pump, more robust than the current pumps, with stainless steel bearing support and a much wider range of models, its name is Ultilobe. A higher range of pressures will be achievable, and it will be able to rotate at a higher speed, so it will be possible to perform CIP cleaning using the same pump.

Furthermore, we are updating our Din-Food range of high flow rate hygienic centrifugal pumps, which can pump liquids at flow rates over 1,000 m3/hour.

Demand

The food and beverage industry is demanding more energy efficient, robust pumps with hygienic design. In any case, choosing the right pump is the first step towards achieving an efficient system. This means obtaining the most accurate information about the process and products to pump as possible.

Correctly calculating load losses, knowing the product’s rheological behaviour, the CIP and SIP conditions, etc., are all essential when it comes to ensuring a pump performs at its energetic and operational best once installed.

INOXPA organises training courses from time to time in order to help our customers learn as much as possible and make the most of our pumps.

Market

Exceptional circumstances have affected the world’s economy in recent years, such as the COVID-19 pandemic, changes to maritime transport, raw material scarcity driving up prices, Russia’s invasion of Ukraine, growing tension between China and the USA, all of which are casting doubt on the future of globalisation.

This retraction in globalisation is creating market uncertainty and seeing protectionist policies implemented in different countries that are changing the rules for world trade.

Despite the difficulties derived from the global situation, we continue to see growth in our main operating sectors, and the food and beverage industries in particular. Thanks to this, the number of orders for INOXPA pumps have been growing over the recent years.

Progress

The state-of-the-art hygienic pumps have to be capable of achieving the highest possible efficacy with the lowest NPSH required, while always operating under hygienic design criteria. For example, INOXPA takes great pride in the HCP centrifugal pump range, which outperforms the competition and has the lowest NPSH required in the market.

Furthermore, the incorporation of Industry 4.0 into the sector sees developments towards connected digital pumps. Constant monitoring of vibration, temperature and pressure values, along with proper analysis of this data, will ensure a user has a more accurate picture of what is happening in their plant, while also enabling better maintenance, ensuring failures are prevented before they occur.

Pump sector evolution

The past 25 years have fortunately seen many positive changes come to the food and beverage sector. The industry is increasingly conscious of using equipment that ensures food safety while operating as efficiently as possible.

Certifications for materials that come into contact with food (such as Regulation (EC) No 1935/2004) are there to prevent any potentially harmful effects to consumer health as far as possible, while ensuring food quality remains unaffected.

Manufacturing pumps in line with hygienic design criteria (such as EHEDG or 3-A) aims to reduce the risk of contamination. Whether manual or automatic (CIP), making pump cleaning as easy as possible is also an objective.

As such, a pump with a hygienic design, made from materials certified for use with foodstuffs and an internal surface roughness of no more than RA 0.8, will mean food manufacturers have to discard fewer product batches due to contamination, along with faster and more effective cleaning, with savings on water, chemicals and energy.

As a result, a company’s costs can be reduced by using hygienic pumps in the food industry.

Furthermore, the industry is increasingly looking to comply with sustainability goals, meaning using the most energy efficient pumps as possible. Achieving the best efficiency essentially means selecting the right pump size, but using variable speed drives to tailor the pump’s rotation speed at the different operating points is also important.

This has all led to buyers furthering their technical knowledge about both pumps and processes, considering the pump’s life-cycle cost (LCC) rather than simply focusing on price.

Contact

Other news

-

23/01/2025

23/01/2025Industrial sourdough plants

INOXPA industrial sourdough plants are a comprehensive solution for producing craft bread on a large scale.

Systems -

20/11/2024

20/11/2024ME-6100 RE: new recirculation tank bottom mixer

This new family of mixers further expands such an important range for our sector as we cover the mixing needs for a wide range of applications.

Mixing -

30/09/2024

30/09/2024Bioreactors: maximum precision and efficiency in every process

INOXPA bioreactors are the definitive solution for more precise, efficient and sustainable biotechnological production.

Systems