INNOVA mini seat valves

22/09/2022

Valves and fittingsINOXPA is launching a new range of “mini” INNOVA seat valves, sizes DN10, DN15, DN20, ½” and ¾”, in two variants - hygienic and aseptic.

These are shut-off and divert single seat valves, INNOVA N and INNOVA K. The hygienic option comes with new sizes compared to the larger valves in its range and the design has changed: the bodies don’t join using clamps as with the larger sizes, they are one-piece bodies machined from a bar.

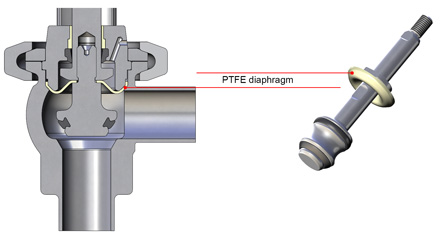

This new structure means that the shaft/seal has also been redesigned and instead of having 2 tapered gaskets, the upper one is now radial, enabling the disassembly of the valve for maintenance.

The aseptic valves aim to avoid potential product contamination from external agents in the environment, such as micro-organisms, bacteria, etc.

As well as being designed and manufactured with optimised materials and finishes for total cleanliness, each valve component that comes into contact with the process is hermetically sealed from the surrounding atmosphere - the valve in this case. A PTFE diaphragm was fitted and attached to the shaft and the internal part of the upper body, so that the shaft section entering and exiting the valve always remains isolated from the process.

These aseptic valves are intended for installations that require high levels of purity, particularly in the pharmaceutical and cosmetic industries, such as manufacturers of injectable medicinal products, creams, etc. They are also essential in some food production phases, as the process control requires very strict levels to minimise the risks of contamination from external sources.

In food-processing plants, there is an aseptic “post-pasteurisation” area where these strict levels of process isolation are found and where only this type of valve can be installed.

By adding this new valve range, INOXPA is making further progress, extending their profile through all production phases and meeting needs from the most demanding industries.

Should you have any queries or need more information, our technical department can provide advice and help you choose the most suitable model based on your needs and requirements.

Contact

Other news

-

27/10/2025

27/10/2025Discover INOXPA’s Partner Portal: efficiency, simplicity and control

We present the Partner Portal, a platform designed to make two-way interaction between customers and INOXPA easier.

-

25/09/2025

25/09/2025UltiLobe: the ultimate lobe pump

UltiLobe is the new generation of rotary lobe pumps with hygienic design, that expands the INOXPA´s portfolio of positive displacement pumps.

Pumps -

30/07/2025

30/07/2025Integral solutions that make the difference

INOXPA have been offering complete, customised solutions for years. We take care of the entire engineering, automation and assembly process.

Systems